Blog

Benefits of Dot Peen Marking

- Fast Marks

- Deep Marks

- Rugged Durable Marks

- Portable Designs and Configuration

- Easy to Operate/Train

- Cost Effective Solutions

Fast Marks

The Superfast series from MECCO features advanced micro-percussion marking units designed for high-speed, precise marking on various materials. These units, available in integrable, portable, desktop, and blended setups, are ideal for automated production lines due to their compact and modular design. Utilizing dot peen technology, they ensure permanent, legible marks even under adverse conditions, making them perfect for industries requiring reliable traceability. This new generation of Superfast markers enhances productivity and compliance with industry standards.

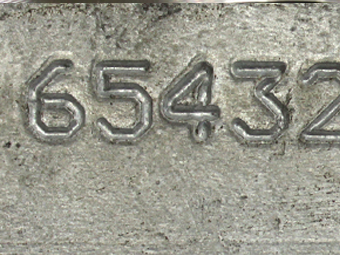

Deep Marks

Dot peen markers are designed to create deep marks quickly and efficiently. Our deep markers can achieve depths of up to 0.5 mm on metals such as steel and aluminum. By selecting the appropriate head size, the dot peen and Vibra Peen marks remain readable even after processes like painting, galvanizing, or plating. SuperFast and Deep Marking dot peen markers enable users to produce deep marks fast.

Durable Marks for Tough Environments and Manufacturing Processes

Portable Designs and Configurations

Our dot peen marking solutions are recognized for being the most compact and lightweight in the industry. We offer dot peen markers in various configurations, including OEM, Benchtop, Portable, and Hybrid, to accommodate the unique style and ergonomic needs of the user.

For applications involving large parts that are difficult to transport to a workbench, we recommend our portable configuration. This design enables the operator to easily lift the marker, position it directly on the surface, and activate it to create the desired mark, all without the need to move the workpiece.

Easy to Operate/Train

Dot peen marking units stand out for their straightforward design and functionality. Unlike certain laser marking systems that demand advanced software, computers, and specialized expertise, dot peen markers offer a user-friendly experience that simply requires a tablet or control pad for operation. The dot peen markers offered by MECCO are equipped with an innovative SMARTbox and a Human Machine Interface (HMI) that prioritizes ease of use. Users can quickly learn to navigate the system, allowing for efficient and effective marking without the steep learning curve associated with more complex technologies.

Cost-Effective Solutions

Dot peen marking solutions are often more budget-friendly than laser marking systems, making them a practical choice for both individuals and businesses that are beginning to navigate the landscape of part marking and traceability. These systems offer an accessible entry point into the world of marking technology. The requirements for precision in both the components and software of dot peen systems are generally less stringent, which contributes to their lower overall cost compared to their laser counterparts. This affordability, along with ease of use, makes dot peen marking an attractive option for those looking to implement marking solutions without the initial investment typically associated with laser technology.

Conclusion

In conclusion, dot peen marking offers a versatile and effective solution for manufacturers seeking reliable traceability in complex environments. Its ability to create durable, legible marks on various surfaces, including rough and uneven material, sets it apart from other marking technologies. Integrating MECCO’s EtherMark technology enhances its value by enabling real-time data access and facilitating informed decision-making in manufacturing processes.

Additionally, the portability and user-friendly design of dot peen marking systems make them accessible for operators, reducing training time and costs. Overall, choosing dot peen marking ensures that manufacturers can maintain high standards of traceability, even in the most demanding conditions.