Blog

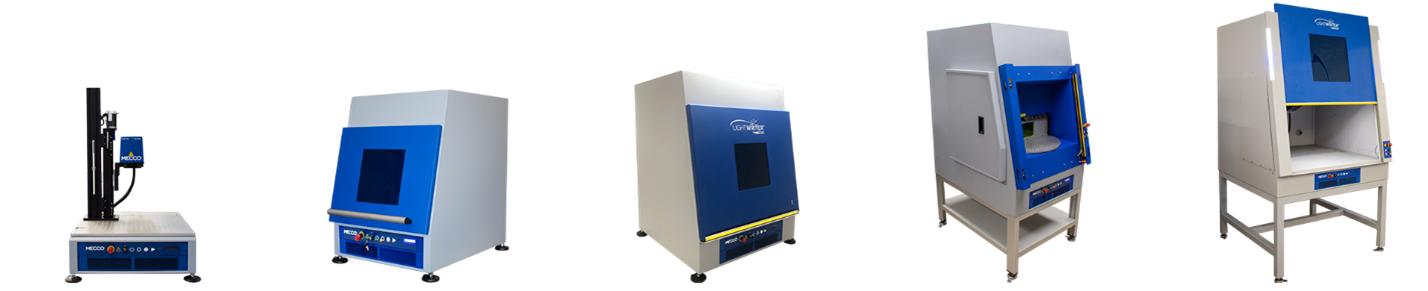

MECCO offers a diverse range of fiber laser solutions, including the SMARTmark® Fiber laser and the SMARTmark VP MOPA Fiber laser. These advanced laser options are seamlessly integrated into MECCO's LightWriter™, LightWriter™ PRO Connect, and custom-engineered solutions, providing customers with versatile and high-performance marking and engraving capabilities. MECCO's fiber laser lineup caters to a wide array of industrial applications, ensuring precision, reliability, and efficiency across various production requirements.

Today, let's dive into the fascinating world of laser cutting! We'll explore the fantastic advantages of using a fiber laser for cutting, the wide range of cutting applications, and explore the laser machines at MECCO that are truly cutting edge.

What is laser cutting?

Laser cutting and laser marking are distinct processes with unique characteristics. In laser marking, a concentrated beam is utilized to discolor, etch, or create a lasting mark on a material. On the other hand, laser cutting uses the same beam to vaporize material at a specified location, resulting in precise cuts or scores on the material. The fundamental disparity lies in the fact that laser cutting removes material entirely, while laser marking does not.

Using a laser for cutting materials instead of traditional tools such as saws and blades offers a multitude of advantages. Laser cutting is exceptionally fast, highly precise, and incredibly efficient. It delivers a clean finish without any physical contact with the material, which reduces the need for consumable materials and maintenance. Additionally, there is no requirement for sharpening, lubrication, or concerns about tools depreciating with use.

What can be cut with a fiber laser?

The Fiber laser is highly versatile and is widely recognized for its ability to precisely mark and cut an extensive variety of materials, with a particular emphasis on metals. The SMARTmark Fiber laser, for instance, can cut nearly all types of metals, such as steel, aluminum, titanium, and tungsten, within specific thickness parameters. Beyond metals, this technology also extends its applicability to cut other materials.

When to use a fiber laser for cutting

Fiber lasers are an ideal choice for cutting across various industries, including automotive and electronic sectors due to their versatility and precision. These lasers can be integrated into existing production lines and are compatible with mounting on robotic arms, gantries, and other automation systems. The broad range of materials that can be effectively cut using fiber lasers, combined with their seamless integration and operation, makes them a popular choice for manufacturers seeking efficient cutting solutions.

Cutting applications include such uses as those listed below:

- Degating applications

- Cutting shapes out of sheet metal

- Creating holes or notches into molded parts

- Other laser-cutting apps

The VP MOPA fiber laser leverages the benefits of traditional fiber lasers and enhances them. Its unique ability to adjust the pulse width gives users the flexibility to generate shorter pulses, resulting in significantly cleaner cut edges compared to those produced by standard fiber lasers. This advanced feature allows for precise and high-quality laser cutting, making the VP MOPA fiber laser stand out in its capabilities.

Fiber Cutting in Action

In 2021, a medical plastics manufacturer approached MECCO with a problem: they needed a method to cut medical tubing cleanly, effectively, and quickly. Our application engineers used the 20W SMARTmark Fiber Laser to create a clean cut. In just 0.4 seconds, our laser produced a 5mm cut line that cleanly went through the plastic tubing.

In 2020, a tier-one automotive company collaborated with our engineering team to create a solution for their production line. They required a method to bore holes into their stainless steel components. Our applications engineers utilized the SMARTmark product line to determine the most effective solution, ultimately selecting the 200W fiber laser. This powerful laser rail could bore a 1.7mm hole into stainless steel in just one second.

Cut to the end

"The right tool for the right job" is an adage that applies to many aspects of life, including laser cutting. While the Fiber laser and the VP MOPA fiber laser can cut various materials, different lasers can cut other materials. For instance, the CO2 laser and the UV lasers are effective for cutting wood, silicones, and sometimes glass. They can also cut various types of plastics, like the Fiber laser.

MECCO has always distinguished itself as a provider of comprehensive traceability solutions, instead of just being a manufacturer of tools. Within our product catalog, you will find a diverse range of standard machines as well as customized engineered solutions. This allows you to efficiently tailor a solution that precisely aligns with your unique requirements.

When looking to select the most suitable laser cutting solution for your specific needs, it is essential to consider various factors, such as whether an OEM, benchtop, or turnkey solution would be the best fit. When you reach out, you will be put in touch with a dedicated team of MECCO application, integration, and service experts. Their expertise will help to guarantee the highest production quality, optimal throughput, reduced time-to-market, and maximum uptime for your operations. Don't hesitate to get in touch with us today for further information and support.