SMARTmark® CO2 Laser Marking Machine

Models: 10W, 30W, 100W

Superior Marking for Wood, Glass & Plastic Parts

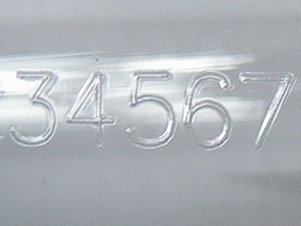

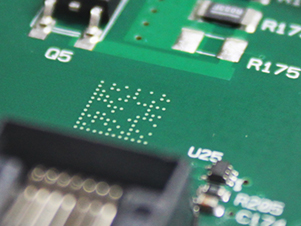

The SMARTmark® OEM CO2 Laser marking and engraving capabilities include marking date codes, serial numbers, and other product identification on wood, glass, rubber, plastics, cardboard, and product packaging.

For product identification and traceability, the CO2 Laser offers the most cost-effective solution in laser marking and engraving technology. Our CO2 lasers can achieve high-speed marking while maintaining mark quality, providing non-contrast marking in plastics as well as ink removal for date coding.

As a result, these compact units commonly replace other marking technologies such as:

- Ink jet

- Dot peen

- Labeling

For easy integration, this system uses embedded control technology to connect with networks via EtherNet/IP. This saves manufacturers time and money by eliminating the need for custom programming of programmable logic controllers (PLCs).

CO2 Laser Sample Marks

- Watch videos of the CO2 laser marking

Request Sample Marking

Contact us to request a sample on your parts

Models

Contact a member of our team today who can guide you to the best solution based on your specific goals.

SMARTmark® CO2 Laser Marking System Features

- Mark organic materials such as wood and glass

- Other applications include degating, cutting, and specialized marks on some plastics and metals

- 45,000+ hours of laser life

- Small 19" rack mount footprint makes it easy to integrate

- Cost-effective solution

- 140mm square mark field (other sizes available)

- No consumables and minimal maintenance help reduce operating costs

- LEC embedded controller

- Compatible with a variety of enclosure options

- Real-time visible live pointer for previewing your mark

- Lightweight, compact design

- Flexibility with cable that can be mounted vertically or horizontally

- 2-Year equipment warranty -- parts and labor

- Laser Customer Success Plans available for preventative maintenance

System Technical Specifications

|

Laser Type |

CO2

|

|

Output Power |

10W, 30W, or 100W |

|

Power Requirements |

10-30W: 110/220 VAC, 10A, 50/60 Hz |

|

Wavelength |

10600nm |

|

M2 |

1.2 ± 0.1 |

|

Operation Mode |

10W: Continuous Wave |

|

Pulse Rep Rate |

10W: N/A |

|

Cooling |

10-30W: Fan Assisted Air Cooling |

|

Scanning Method |

XY galvanometer |

|

Rail Weight |

10W: 45 lbs 30W: 50 lbs 100W: 91 lbs |

| Rail Dimensions | 10W: W 30.51" x H 7.06" x D 7.00" 30W: W 27.56" x H 7.36" x D 7.49" 100W: W 43.88" x H 9.61" x D 8.21" |

|

Cable Length |

9.8' |

|

Controller Dimensions |

10W: W 18.99" x H 6.98" x D 17.95" |

|

Accuracy |

3.5 μm across field |

|

Max Line Speed |

2,000 mm/sec using 200mm lens |

|

Controls |

Industrial LEC-embedded laser marking controller |

|

Communications |

Ethernet TCP/IP, Ethernet/IP™, Modbus TCP, RS232 |

|

Approvals |

CE |

|

Warranty |

2 Years |

|

Documentation |

USB Flashdrive with Operator’s Manual & Integration Guide |

Lens Configurations

30W Lens Options

|

Lens |

Marking Field |

Working Distance |

|---|---|---|

|

100mm |

70mm x 70mm (2.8” x 2.8”) |

87.8mm (3.46”) |

|

200mm |

140mm x 140mm (5.5” x 5.5”) |

189.4mm (7.46”) |

|

360mm |

250mm x 250mm (9.8” x 9.8”) |

343.0mm (13.5”) |

|

450mm |

331mm x 331mm (13.0” x 13.0”) |

446.1mm (17.56”) |

10W and 100W Lens Options

|

Lens |

Marking Field |

Working Distance |

|---|---|---|

|

100mm |

70mm x 70mm (2.8” x 2.8”) |

81mm (3.19”) |

|

200mm |

140mm x 140mm (5.5” x 5.5”) |

184mm (7.24”) |

|

360mm |

250mm x 250mm (9.8” x 9.8”) |

351mm (13.82”) |

|

450mm |

387mm x 387mm (15.2” x 15.2”) |

454mm (17.87”) |

Laser Marking Software

MECCO lasers all use WinLase by MECCO laser marking software with unique options configured to your needs.

We also offer custom Graphical User Interfaces to help ensure that ease-of-use, automation, database integration and vision inspection meet the needs of your project.

SMARTmark® CO2 Product Resources

- Software Files

- Manuals

- Integration Guides

- Engineering Drawings

- Troubleshooting Videos

- Software Training Videos

Go To Downloads

Laser Product Options

-

OEM Models

An OEM (or U-Model) is the core product for making traceability marks on your parts. It consists of the laser rail with controller and is the choice for machine builders to integrate marking into a larger turnkey solution. -

Enclosures & Workstations

Lasers can be added to standalone, configurable enclosures that are designed to meet CDRH Class 1 safety regulations and available in a range of sizes to meet the requirements of your parts. Learn more about the LightWriterTM and LightWriter PRO Connect series. -

Turnkey Solutions

SMARTmark® Laser Marking Systems are configurable to your part and process automation requirements. With our Turnkey Laser Solutions, we can design and manufacture an enclosure to meet your needs in part handling, vision, software and database integration.

Improving Branding Efficiency

CASE STUDY: Stanley Furniture

The company had been placing plaques inside the drawers of the dressers to indicate that they were made in America and wanted to explore more cost-effective and efficient ways to boldly convey their mark.