Blog

Manufacturing firearms can be challenging. Industry regulations, federal laws, and the challenges that normally come with producing manufactured goods create a tricky maze for you to navigate to find the best solutions. At MECCO, we are experts in track-and-trace technology, laser marking, and pin marking. We can help you understand the elements of marking and engraving on firearms. These elements are:

- Permanent Serial Numbers and Traceability

- Functional and Decorative Marking

- Finding the Right Laser for your Materials

Understanding these elements is crucial for manufacturers aiming to enhance product integrity, comply with regulations, and elevate their brand identity in this competitive marketplace.

Permanent Serial Numbers and Traceability

Firearms are part of a highly regulated industry, where serial numbers, barcodes, and other tracking methods play a crucial role in adhering to federal laws and industry regulations, in accordance with regulations from the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) and the National Firearms Act (NFA).

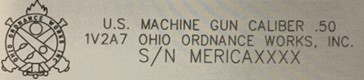

The Gun Control Act of 1968 requires a serial number to appear on the firearm. All firearms sold in the United States need to have the following marked on the frame or receiver: serial number, manufacturer name, country of origin, model designation, and caliber. If the weapon is imported, the manufacturer also needs to include the name of importer, and the importer’s city and state. Navigating these laws and manufacturing products that comply with such rules can be challenging.

.jpg)

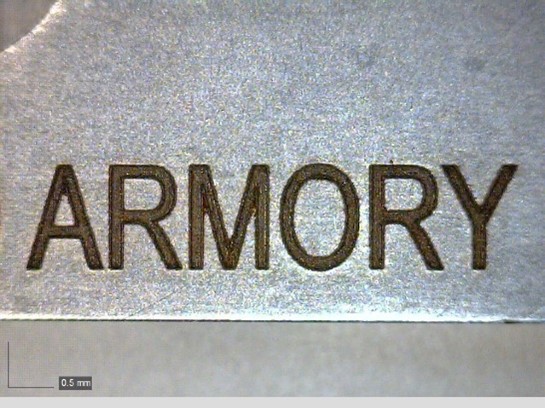

According to the ATF, identification marks must be clearly visible and not easily removed or erased. The marks must have a minimum depth of 0.003 inches, measured from the flat surface of the metal rather than the peaks or ridges. MECCO offers a variety of laser and pin marking solutions that can produce marks of this depth with high contrast, ensuring compliance with ATF requirements.

Track-and-trace systems are essential for ensuring that firearms are produced with the highest quality standards while meeting legal requirements. In addition to graphics and logos, MECCO direct part marking solutions deliver permanent, highly readable serial numbers to identify and track firearm parts through the supply chain. A robust track-and-trace system guarantees that each firearm is produced with exceptional quality and adheres to legal specifications. This capability allows for precise manufacturing process tracking, documenting where and when each firearm was crafted and the details of its sale. This thorough record-keeping creates a clear chain of custody for every firearm, enhancing accountability and transparency.

As the firearm industry continues to evolve, it faces new challenges and changing regulations. Our team of experts and skilled engineers is committed to providing support tailored to your needs, ensuring your operations remain efficient, compliant, and poised for success in this dynamic environment.

Functional and Decorative Marking

Marks on a firearm do not have to be limited to legal and federal requirements. They can be created to assist the user in operating the firearm, or purely for aesthetic purposes. Due to the extreme conditions that some firearms may encounter, as well as the heat and wear they experience from repeated use, a laser or pin marking solution is more advisable than using print or inkjet methods.

Sighting in a rifle requires precision and accuracy. Shooters are assisted by graduated marks on the top of the rifle where the sights are and can adjust them accordingly. Other marks that help with functionality indicate the mode of fire and safety on the receiver.

Magazines feature viewports on the back so one can see the bullets as they are loaded in, but some manufacturers are marking pre-measured areas on the magazine with numbers indicating the number of bullets loaded. These could be marked with a fiber laser, like those in the LightWriter™ laser marking enclosures, and they could be marked easily in batches with a custom fixture created by our integrations team.

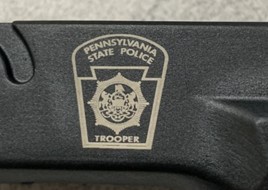

Part marking offers more benefits than just traceability and functionality. Firearms are like any other product on the market, and manufacturers seek the best ways to apply their unique mark to their creations.

With MECCO’s WinLase® software, you can create a vector-based design file and easily import it into the program. From there, you can apply the settings and properties of the laser mark best suited for the material you are marking. Custom designs are simple to

create and even easier to mark with WinLase.

Materials

Firearms are made from various materials, each requiring specific methods for marking. Our engineers are prepared to collaborate with you to identify the best solution for your requirements. Here are just a few examples of the materials that our lasers can effectively mark.

Carbon Steel/Stainless Steel

Steel is commonly used for the barrel or receiver of a gun. Marks on these components may include serial numbers, product information, or decorative elements.

Many lasers in the SMARTmark® OEM product line can mark on steel. Our lasers easily create marks that meet the minimum depth requirements for engraving.

Our SMARTmark Fiber and SMARTmark VP MOPA laser machines can create a carbon migration or an anneal mark, resulting in a clean and smooth finish on stainless steel, free from the brown burn marks that can make a mark appear blurry.

For more traditional markings, such as serial numbers or product information, a dot peen machine or a laser can be used. Our systems can integrate with your product databases to generate sequential serial numbers, which can easily be incorporated into any automated solution.

Aluminum

Firearms used by the military often incorporate lightweight materials, including various plastics and aluminum. It is not uncommon to find aluminum receivers and frames in some firearms. Additionally, components such as slides, heat shields, foregrips, and other attachments may be made from aluminum or anodized aluminum.

Some products in our SMARTmark OEM line can create marks on anodized aluminum without destroying the anodization. These lasers include the SMARTmark VP MOPA and the SMARTmark CO2 laser marking machines.

Titanium

While not commonly used, titanium is a material used to manufacture certain firearms. It is lightweight, strong, heat-resistant, and corrosion resistant. Marking titanium presents some challenges due to its hardness, which can make dot peen or stamping difficult. However, marking lasers that use annealing or carbon migration techniques can produce clean and smooth marks, like those on steel.

Plastics

MECCO provides various laser marking solutions suitable for marking plastics. The SMARTmark® VP MOPA, along with the green and UV laser systems, can create sharp, high-contrast marks on plastic surfaces that are clear and easy to read. These solutions are becoming increasingly important as firearms incorporate more plastic components and as third parties begin to sell 3D-printed parts for firearms.

Wood

Wooden stocks and handles in firearms are becoming increasingly rare, but they are not completely obsolete. Many old surplus weapons and historical firearms still feature wooden components, and collectors may wish to replace warped wood with new pieces. The SMARTmark® CO2 laser can engrave designs on wood, allowing collectors to preserve wooden components while adding custom laser markings.

Conclusion

The effective marking of firearms is a multifaceted process that not only enhances traceability and compliance with regulations but also plays a vital role in branding and aesthetics. As this industry evolves, manufacturers must leverage advanced marking technologies, such as fiber lasers and integrated systems, to produce high-quality marks on a variety of materials, including metals, plastics, and wood.

The ability to create custom designs and manage serialization efficiently can significantly enhance product integrity and brand recognition in a competitive market. By understanding and implementing these marking solutions, manufacturers can meet the demands of both regulatory requirements and consumer expectations, ultimately contributing to the success and reputation of their products in the firearms industry.

Explore our SMARTmark OEM laser marking machines for a wide range of options for marking firearms. For ease of use and a laser-safe enclosure, learn more about our LightWriter™ and LightWriter™ PRO Connect Enclosed workstations. Check out our dot peen and scribe systems for deep marks that can survive corrosion, wear, and galvanization. For more in-depth solutions, feel free to contact our team of engineers for a system that best suits your needs, or schedule a demo to see how we can help you.