Dot peen deep engraving is a high-speed, durable marking process that ensures permanent traceability—even after challenging post-processes like painting, galvanizing, or exposure to extreme conditions. Unlike surface-level marking, dot peen technology creates deep engravings quickly and efficiently, making it ideal for parts that must endure harsh environments. From deep downhole drilling to metal fabrication, agricultural machinery, and other oil and gas applications, deep marking with dot peen excels where long-lasting identification is necessary.

Materials and Applications for Dot Peen Deep Engraving

Dot peen deep engraving is compatible with metals under 60 HRC, such as structural steel and aluminum, making it a go-to solution for industrial applications. Its versatility, however, extends across a wide range of uses and materials.

Best Materials for Dot Peen Deep Engraving:

• Metals under 60 HRC

• Typically steel or aluminum

Example Products:

● Round pipes

● Ingots

● Flanges,

● Steel beams

● Car frames

The depth of these marks provides more than just permanence—it offers natural resistance to corrosive, acidic, or abrasive environments. This durability ensures readability even after processes that might otherwise obscure traditional markings.

Common dot peen deep marking applications include:

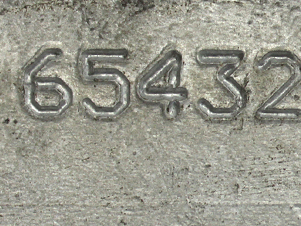

● Serial numbers

● Batch numbers

● Dates

● 2D Barcoding

Galvanization, painting, or plating are all processes that can normally erase text or barcodes. Any application that requires a post-process – heavy paints or galvanization – usually needs a deep dot peen mark to maintain readability.

Industries Relying on Dot Peen Deep Marking

Many industries depend on the precision and durability of dot peen marking systems for traceability in demanding environments, including automotive and aerospace, mining, castings, forgings, rolled metal sheets, structural steel and aluminum, heavy industrial gears and bearings, and other parts exposed to harsh operating conditions.

Dot Peen in Automotive: Automotive companies use deep marking technology to ensure compliance with regulatory standards with VINs and other identifiers. Inadequate depth can lead to a vehicle getting rejected, making dot peen an essential solution to the stringent and non-stringent regulation factors.

Common automotive applications include:

● Vehicle Identification Numbers (VIN)

● Chassis and frame marking

● Tractors and heavy machinery parts

● Axles

● Driveshafts

● Engine blocks

Dot Peen in Metal Fabrication & Manufacturing: Dot peen markers are widely used in fabrication shops and manufacturing floors, where components require heavy-duty, corrosive-resistant markings that can withstand tough processes. Dot peen deep marking is ideal for marking pipes, tubes, flanges, steel beams and columns, excavators, infrastructure components, and all parts used in indoor and outdoor manufacturing processes.

Dot Peen in Oil & Gas: Parts used for work in the oil and gas industries must endure extreme environments, making deep engraving essential for traceability. Downhole pipes, storage tanks, and drilling equipment face harsh conditions that make dot peen the ideal deep marking solution.

Dot Peen in Aerospace: While less common in aerospace, dot peen is still used for marking fuselage panels, airframe parts, and engine components.

Why Industries Choose Dot Peen Deep Marking Systems

Dot peen engraving stands out for its depth, efficiency, and affordability compared to alternative methods. Here’s why industries prefer it:

• Unmatched Depth: Achieves deep marks quickly—essential for lasting identification.

• Cost-Effectiveness: Unlike CNC machines, which are larger and pricier, dot peen delivers comparable depth at a fraction of the cost.

• Portability & Versatility: Easily marks large or awkwardly shaped parts.

• Enhanced Safety: A safer alternative to tools like the Hilti gun.

• Permanent Readability: Tamper-resistant marks combat counterfeiting effectively.

MECCO’s Dot Peen Deep Engraving Solutions

As industries increasingly prioritize traceability, dot peen engraving is rapidly replacing traditional hand stamping and other outdated methods. MECCO leads the market with cutting-edge dot peen technology, rigorously tested against competitors and continuously developing solutions that meet evolving industry demands.

MECCO’s dot peen markers deliver unmatched precision, speed, and durability. Our products achieve depths up to 0.5mm at optimal speed and offer

turnkey pin marking solutions with an intuitive Graphical User Interface (GUI) that integrates seamlessly into your existing workflows.

Our proprietary

Vibra Peen™ technology produces the fastest, deepest marks in the world, with standout models like the N34 and 100x17 N20 on the Superfast or Standard series.

For heavy-duty applications—such as structural steel or oil and gas—the N34 is a powerhouse. Its flexible marking head operates in any position, ensuring portability and ease when marking large parts in extreme environments.